With over 30 years’ experience in designing, manufacturing, and installing beautifully handcrafted glass and timber structures, we understand the importance of innovation in maintaining our position as industry leaders. To ensure we innovate in a way that not only benefits our business but allows us to deliver the highest possible standard of service and product, we strike a careful balance between the use of modern technology and preserving traditional methods, reinforcing our reputation for excellence within the market.

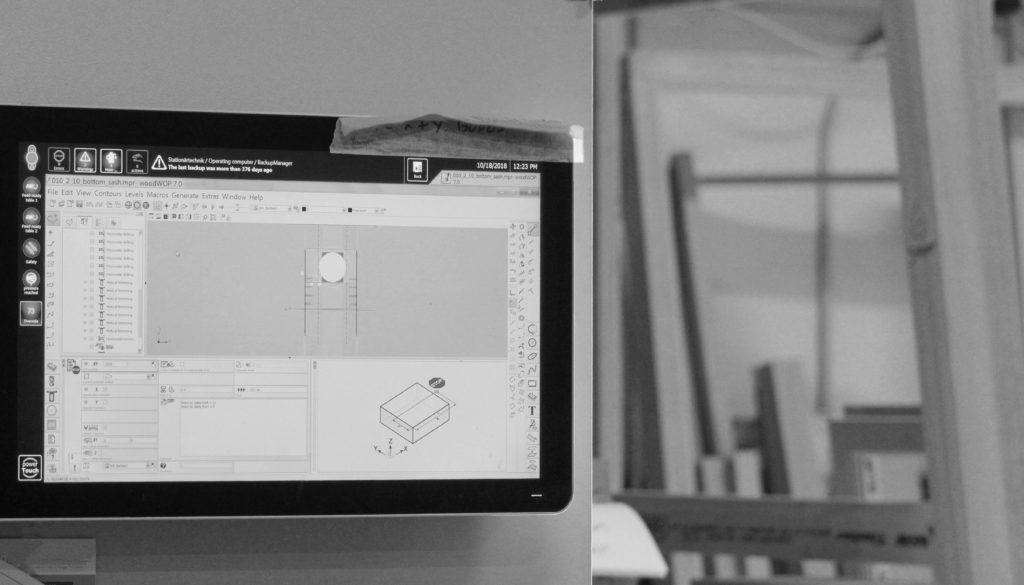

In 2018, we made the strategic decision to integrate Computer Numerical Control (CNC) technology into our manufacturing process. This integration streamlined our processes and enhanced our precision, allowing us to deliver exceptional results to our clients without compromising the true core of our company, its people.

Reflecting on our investment in CNC technology, we decided to share some of the reasons why it has proven to be a valuable addition to our company and to our clients:

Increased Precision:

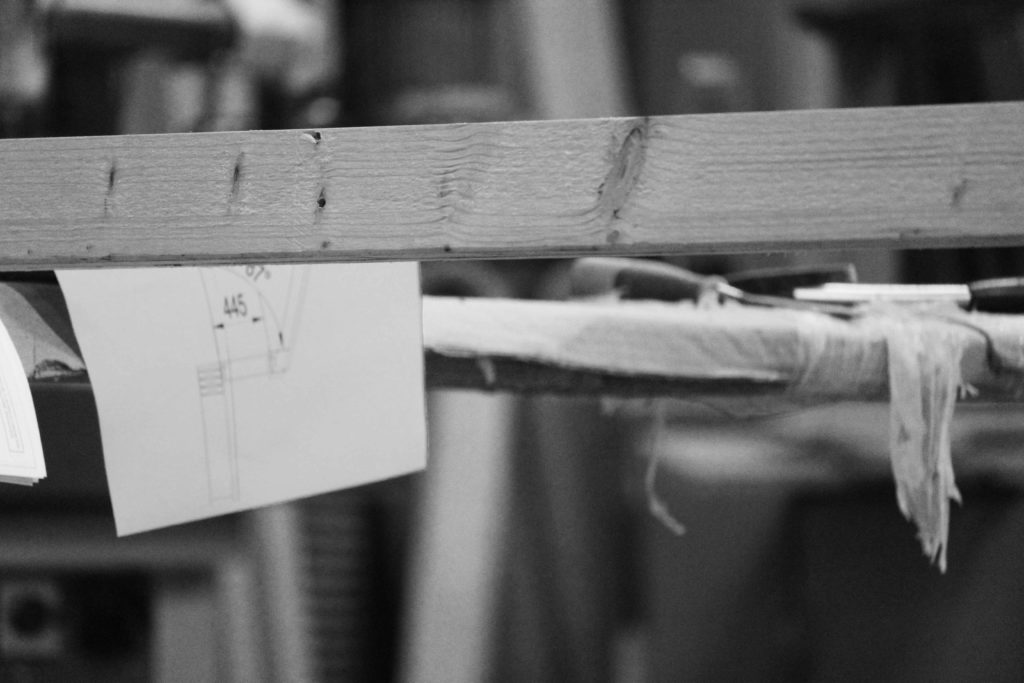

CNC machines offer increased precision in cutting and shaping materials compared to traditional manual methods. Using precise computer calculations, each cut is accurate and consistent, resulting in a higher quality end product.

Efficiency:

CNC machines significantly improve manufacturing efficiency. Capable of operating at much faster speeds than manual methods, they enable higher production rates. Furthermore, CNC machines can run 24/7, providing uninterrupted production and reducing the need for manual labour.

Our made-to-order windows and doors production, for example, has increased by 25% per month, adding considerable value to our business. This growth enabled us to redirect our skilled craftsmen towards meeting the growing demand for creating bespoke hardwood conservatories, orangeries, sun lounges, extensions, canopies, and garden rooms.

Versatility:

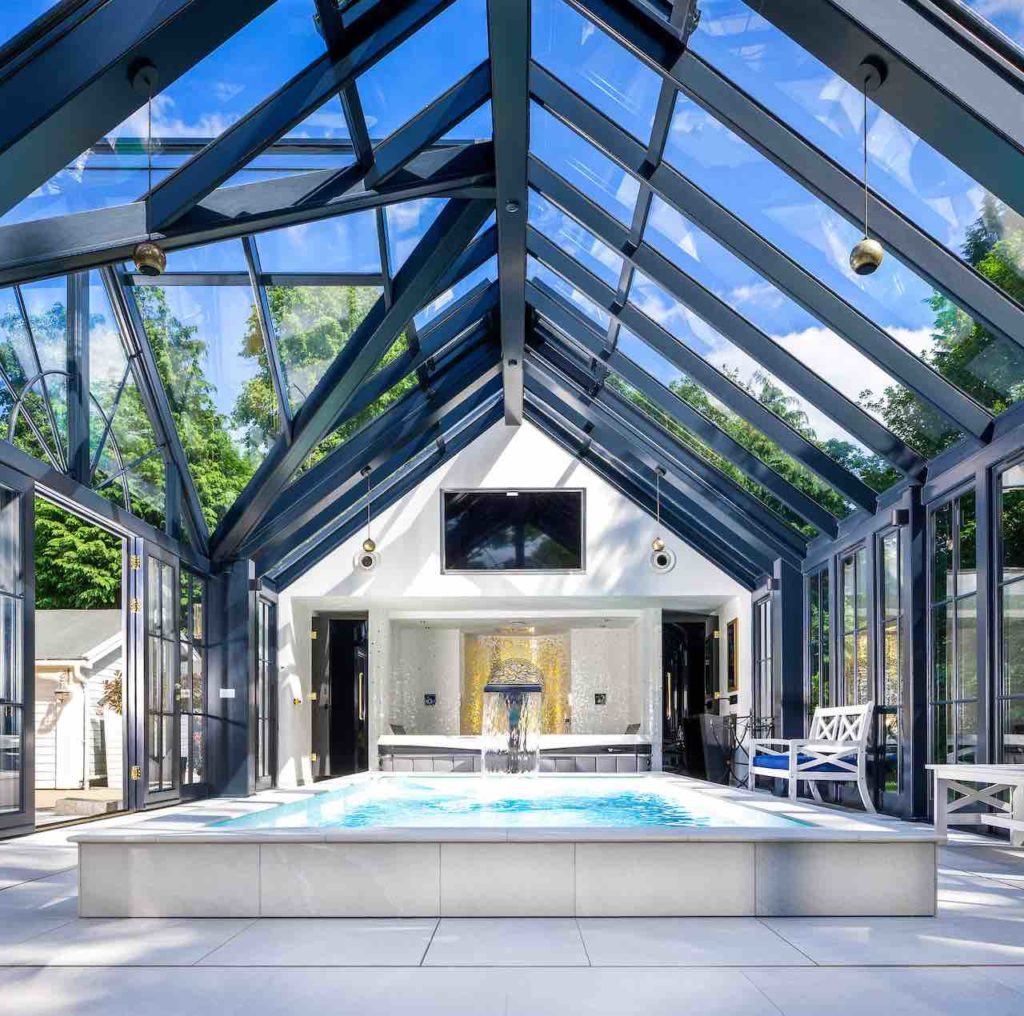

Another advantage of using a CNC machine is its versatility. It can be programmed to produce a variety of different shapes and designs, making it a valuable tool for producing custom-made hardwood glass and timber structures. This versatility allows us to produce a wider range of products, meeting the diverse needs of both residential and commercial markets.

Reduced Waste:

CNC machines also minimise waste by producing more accurate cuts and shapes. This not only reduces material waste but also lowers production costs, making it a cost-effective solution for manufacturers.

By offering unparalleled precision, efficiency, and versatility, the CNC machine has enhanced our in-house capabilities and strengthened our ability to deliver bespoke hardwood glass and timber projects to residential and commercial markets nationwide.

This investment in innovation demonstrates our continued commitment to each and every one of our clients and with a strong workforce of 60 skilled men and women, many of whom work alongside this impressive technology every day, we believe the results speak for themselves.